The tanks are refrigerated and insulated as the main requirement of dairy tanks is that they are able to keep the milk and dairy products at a certain cold temperature. This is important to maintain health standards of the products as bacteria and diseases can grow rapidly on dairy products that are not refrigerated and processed in a timely manner. Read More…

Here at Frain Industries, Inc. we offer an extensive line of stainless steel tanks. These tanks come in a wide range of shapes and sizes based on their application. Our tank sizes range from 5 gallons to 10,000 gallons and these tanks can be customized to meet your application needs.

For 50 years G & F Manufacturing has been a leading quality stainless steel tank manufacturer for many industries, including pharmaceutical, food & beverage. Their storage containers offer quality workmanship & durability.

Rexarc’s focus is on the fabrication of custom stainless and carbon steel pressure vessels. We welcome applications with pressures between 500 and 5,000 psi. After nearly 100-years of being in business, Rexarc has the knowledge, attitude, equipment, and processes to support your needs in vessel production and value add services of piping, instrumentation, paint, and other controls...

At Weston & Associates, we take pride in our extensive range of stainless steel tanks, meticulously designed and crafted to cater to a myriad of industries. Our tanks are not just products; they are a testament to our relentless pursuit of quality and functionality. We understand that each client is unique, and our diverse portfolio of tanks reflects our adaptability in customizing solutions that ...

At True-Blue Welding and Fabrication LLC, we pride ourselves on our expertise in crafting high-quality stainless steel tanks. Our journey is defined by a relentless pursuit of perfection and a commitment to meeting the diverse needs of our clients. Join countless satisfied clients who have entrusted us with their most demanding projects and experience the True-Blue difference today.

Badger Fabrication is a family owned, custom stainless steel and waterjet cutting fabricator. We serve the food, diary and construction industry. Our state-of-the-art capabilities and craftsmanship will provide the quality, design and performance your application requires. We can provide finished products such as single shell tanks, mixers, enclosures, sanitary fittings, conduit hangers and more.

We offer a full range of stainless steel tanks such as vertical single wall tanks, process columns, portable mix tanks, cooking & pasteurizing kettle, specialty tanks, and more. We are committed to assisting you with finding a tank that meets your needs and these reliable products are very affordable.

More Dairy Tank Manufacturers

The dairy industry has some of the highest standards in terms of requirements for cleanliness and processing materials, and tanks used for milk storage need to be inspected to ensure their design, construction and material choice are the most ideal for the purpose. Dairy tanks are made of stainless steel as it is one of the most sanitary manufacturing options. It is easy to clean and does not stain nor does it absorb any of the products it comes into contact with. Furthermore, it is corrosion resistant and will not rust, even when exposed to moisture for prolonged periods of time.

Other advantages to using stainless steel storage tanks include the durability and cost-effectiveness of the material. Stainless steel is also commonly used in other food processing applications, such as mixing tanks or water tanks, due to these properties.

Milk is transported using sterile tubes from the milking machines into the dairy tank. It is often cooled using a heat exchanger as the milk is warm when collected directly from the cows. The tanks can range in size from as low as 100 gallons up to thousands of gallons, depending both on the size of the dairy and the processing and transportation capabilities. It is stored temporarily in those holding tanks until being transferred to refrigerated trucks for transportation to processing and packaging plants.

Dairy tanks are a necessary element of dairy product processing, and yet there are points to consider when determining the design specifics of a tank. Most importantly, a tank needs to be able to be cleaned and sanitized, and inspected for rust or other degradation.

Tanks need to be thoroughly cleaned in between each load of milk and therefore need to be durable enough to withstand repeated cleaning as well as simple enough to ensure thorough sanitization with each clean. While stainless steel is the most common material used in dairy tank construction, some glass, plastic, or rubber products are also used and these need to be high quality materials to ensure sanitary processes.

55 Gallon Drums

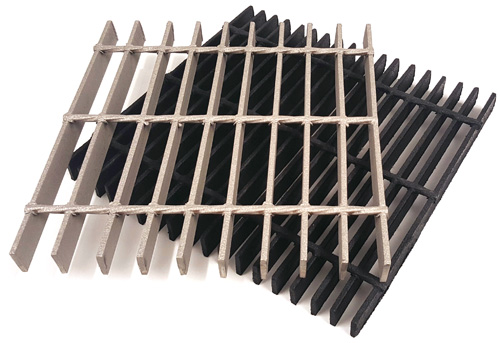

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services