Of the three types of silos-tower, bag and bunker-stainless steel tower silos are the most widely used. Mainly found on a farm and used in the agricultural industry to store crops or animal feed, known as silage, stainless steel silos range in size and capacity, sometimes containing hundreds of tons of storage. Read More…

Here at Frain Industries, Inc. we offer an extensive line of stainless steel tanks. These tanks come in a wide range of shapes and sizes based on their application. Our tank sizes range from 5 gallons to 10,000 gallons and these tanks can be customized to meet your application needs.

For 50 years G & F Manufacturing has been a leading quality stainless steel tank manufacturer for many industries, including pharmaceutical, food & beverage. Their storage containers offer quality workmanship & durability.

Rexarc’s focus is on the fabrication of custom stainless and carbon steel pressure vessels. We welcome applications with pressures between 500 and 5,000 psi. After nearly 100-years of being in business, Rexarc has the knowledge, attitude, equipment, and processes to support your needs in vessel production and value add services of piping, instrumentation, paint, and other controls...

At Weston & Associates, we take pride in our extensive range of stainless steel tanks, meticulously designed and crafted to cater to a myriad of industries. Our tanks are not just products; they are a testament to our relentless pursuit of quality and functionality. We understand that each client is unique, and our diverse portfolio of tanks reflects our adaptability in customizing solutions that ...

At True-Blue Welding and Fabrication LLC, we pride ourselves on our expertise in crafting high-quality stainless steel tanks. Our journey is defined by a relentless pursuit of perfection and a commitment to meeting the diverse needs of our clients. Join countless satisfied clients who have entrusted us with their most demanding projects and experience the True-Blue difference today.

Badger Fabrication is a family owned, custom stainless steel and waterjet cutting fabricator. We serve the food, diary and construction industry. Our state-of-the-art capabilities and craftsmanship will provide the quality, design and performance your application requires. We can provide finished products such as single shell tanks, mixers, enclosures, sanitary fittings, conduit hangers and more.

We offer a full range of stainless steel tanks such as vertical single wall tanks, process columns, portable mix tanks, cooking & pasteurizing kettle, specialty tanks, and more. We are committed to assisting you with finding a tank that meets your needs and these reliable products are very affordable.

More Stainless Steel Silo Manufacturers

Silos are typically the largest stainless steel tank on the market, ranging from 10 to 90 feet in diameter and 30 to 275 feel in height. Because stainless steel is easy to clean and has no pores that would absorb or release impurities, these silos are used in the chemical, food processing, mining, pharmaceutical, plastics and water works industries holding substances like milk, crushed limestone powder or corn seed.

Stainless steel is an effective conductor of thermal heat and resists high temperature oxidation which makes it suitable for outdoor use in many different climates. It's a versatile and common metal that is resistant to corrosion, staining, peeling and cracking. The familiar cylindrical shape of these silos is meant to resist hydraulic pressure, and they always contain at least one manway, or opening, for pressure control.

The process of constructing a stainless steel silo begins with steel, an alloy metal consisting mostly of iron. Chromium is added to the metal; the percentage of chromium determines the grade and corrosion resistance of the final product. Steel and the alloys are melted together in an electric arc furnace and then annealed, a process that alternately heats and cools the steel until hardened.

A thin flexible layer of chromium oxide forms on the outside surface, coating it and in essence sealing it off from abrasive substances. For a silo, the stainless steel is roll-formed. A long strip of stainless steel is fed through a series of rollers that gradually bend the steel into shape.

Since the stainless steel is worked in a cold state, the results are typically lighter and stronger than if the steel had been stretched while hot. After the large curved sheets are cut and prepared, they can be fastened together with bolts or welded, which ensures a seamless watertight construction. If the size allows it, silos are transported on a special delivery truck and then erected by a crane.

Depending on the intended use of the silo, a 45 or 60 degree stainless steel cone can be fitted on the bottom to allow a consistent flow of material. Other nozzles, doors, pipes and fittings are added; some silos require heating, refrigeration or have an agitator installed. The stainless steel silo can sit on the ground or be supported on a stand to allow for easy access to the material inside. The stands vary in size and strength as well as design and can be elevated, legged or skirted.

55 Gallon Drums

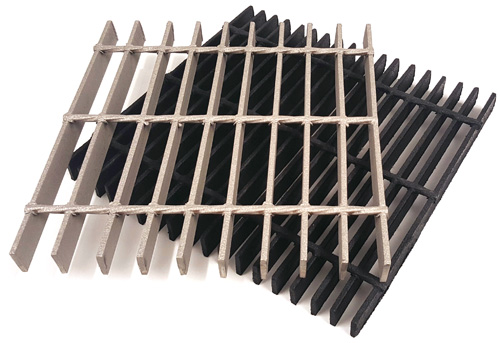

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services