The food and beverage industries prefer to use stainless steel vats because the steel is chemically neutral and will not add flavors or impurities. It is also very easy to clean and keep sanitary. Read More…

Here at Frain Industries, Inc. we offer an extensive line of stainless steel tanks. These tanks come in a wide range of shapes and sizes based on their application. Our tank sizes range from 5 gallons to 10,000 gallons and these tanks can be customized to meet your application needs.

For 50 years G & F Manufacturing has been a leading quality stainless steel tank manufacturer for many industries, including pharmaceutical, food & beverage. Their storage containers offer quality workmanship & durability.

Rexarc’s focus is on the fabrication of custom stainless and carbon steel pressure vessels. We welcome applications with pressures between 500 and 5,000 psi. After nearly 100-years of being in business, Rexarc has the knowledge, attitude, equipment, and processes to support your needs in vessel production and value add services of piping, instrumentation, paint, and other controls...

At Weston & Associates, we take pride in our extensive range of stainless steel tanks, meticulously designed and crafted to cater to a myriad of industries. Our tanks are not just products; they are a testament to our relentless pursuit of quality and functionality. We understand that each client is unique, and our diverse portfolio of tanks reflects our adaptability in customizing solutions that ...

At True-Blue Welding and Fabrication LLC, we pride ourselves on our expertise in crafting high-quality stainless steel tanks. Our journey is defined by a relentless pursuit of perfection and a commitment to meeting the diverse needs of our clients. Join countless satisfied clients who have entrusted us with their most demanding projects and experience the True-Blue difference today.

Badger Fabrication is a family owned, custom stainless steel and waterjet cutting fabricator. We serve the food, diary and construction industry. Our state-of-the-art capabilities and craftsmanship will provide the quality, design and performance your application requires. We can provide finished products such as single shell tanks, mixers, enclosures, sanitary fittings, conduit hangers and more.

We offer a full range of stainless steel tanks such as vertical single wall tanks, process columns, portable mix tanks, cooking & pasteurizing kettle, specialty tanks, and more. We are committed to assisting you with finding a tank that meets your needs and these reliable products are very affordable.

More Stainless Steel Vat Manufacturers

Stainless steel conducts heat well, allowing for precise management of the substance inside, and it can be refrigerated to maintain lower temperatures. Caustic liquids will not easily damage the vat, though lower grades of stainless steel can be incompatible with certain wines and ciders. Vats are typically constructed from food grade 304 stainless steel which is also called 18/8 or 18/10 because of the ratios of chromium and nickel.

Stainless steel is produced when steel and alloys are melted together. Once homogeneous, the molten metal is hardened through the annealing process.For a vat, the cooled steel is fed through a series of rollers that gradually bend it into a rounded shape. The curved sheets of stainless steel are then cut, finished and welded together for a seamless watertight result. The majority of stainless steels vats are designed to keep the contents hot or cold.

High density polyurethane or a similar material can be wrapped around the vat then covered with aluminum or another sheet of stainless steel to keep the contents of the stainless steel tank warm and insulated. For refrigeration, typically a cooling jacket will be used. Similar in technique to insulation, a jacket is fastened on the outside of the vat and circulates a cooling agent like glycol, ammonia or water around the container for temperature control. An alternative to a jacket is a double-walled vat where the coolant runs between the two walls. Another integral feature is the manways, which are openings used as access doors, sampling ports or fill openings.

Agitators are also commonplace, especially when the vat is used for food processes like mixing or separating liquids. Some stainless steel vats have lids that can easily be lifted or removed while others are self-enclosed tanks with an atmospheric vent feature to release the pressure inside. Because of the weight and potential pressure building inside vats, especially those used for fermentation, vats should be placed on an adequate foundation like concrete or asphalt. Vats typically do not require a separate stand but are sturdy enough to stand on their own.

55 Gallon Drums

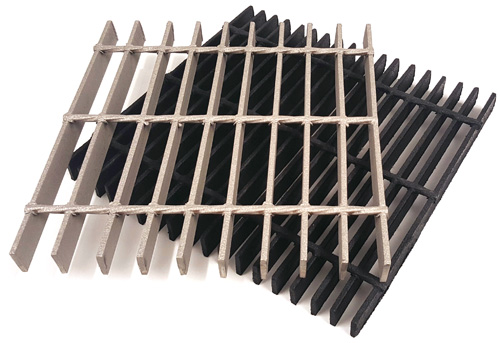

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services