Food grade tanks are constructed in compliance with Food and Drug Administration regulations regarding the handling and processing of food for general consumption. Many are made with FDA approved coated carbon steel and stainless steel that is thermally cured. Additionally, high density polyethylene or polyurethane are used to manufacture food grade storage tanks due to their resistance to solvents and chemicals. Read More…

Here at Frain Industries, Inc. we offer an extensive line of stainless steel tanks. These tanks come in a wide range of shapes and sizes based on their application. Our tank sizes range from 5 gallons to 10,000 gallons and these tanks can be customized to meet your application needs.

For 50 years G & F Manufacturing has been a leading quality stainless steel tank manufacturer for many industries, including pharmaceutical, food & beverage. Their storage containers offer quality workmanship & durability.

Rexarc’s focus is on the fabrication of custom stainless and carbon steel pressure vessels. We welcome applications with pressures between 500 and 5,000 psi. After nearly 100-years of being in business, Rexarc has the knowledge, attitude, equipment, and processes to support your needs in vessel production and value add services of piping, instrumentation, paint, and other controls...

At Weston & Associates, we take pride in our extensive range of stainless steel tanks, meticulously designed and crafted to cater to a myriad of industries. Our tanks are not just products; they are a testament to our relentless pursuit of quality and functionality. We understand that each client is unique, and our diverse portfolio of tanks reflects our adaptability in customizing solutions that ...

At True-Blue Welding and Fabrication LLC, we pride ourselves on our expertise in crafting high-quality stainless steel tanks. Our journey is defined by a relentless pursuit of perfection and a commitment to meeting the diverse needs of our clients. Join countless satisfied clients who have entrusted us with their most demanding projects and experience the True-Blue difference today.

Badger Fabrication is a family owned, custom stainless steel and waterjet cutting fabricator. We serve the food, diary and construction industry. Our state-of-the-art capabilities and craftsmanship will provide the quality, design and performance your application requires. We can provide finished products such as single shell tanks, mixers, enclosures, sanitary fittings, conduit hangers and more.

We offer a full range of stainless steel tanks such as vertical single wall tanks, process columns, portable mix tanks, cooking & pasteurizing kettle, specialty tanks, and more. We are committed to assisting you with finding a tank that meets your needs and these reliable products are very affordable.

More Food Grade Tank Manufacturers

The food processing industries, such as brewing, meat packing, and bakeries, depend on well designed and constructed food storage tanks to safely and hygienically store their ingredients. Stainless steel tanks are used to mix meat with additives or blend sausage. The brewing industry depends on food grade tanks for use as fermentation vats for adding yeast, while 304 stainless steel tanks are used in the citrus and fruit juice industry from harvest to final product.

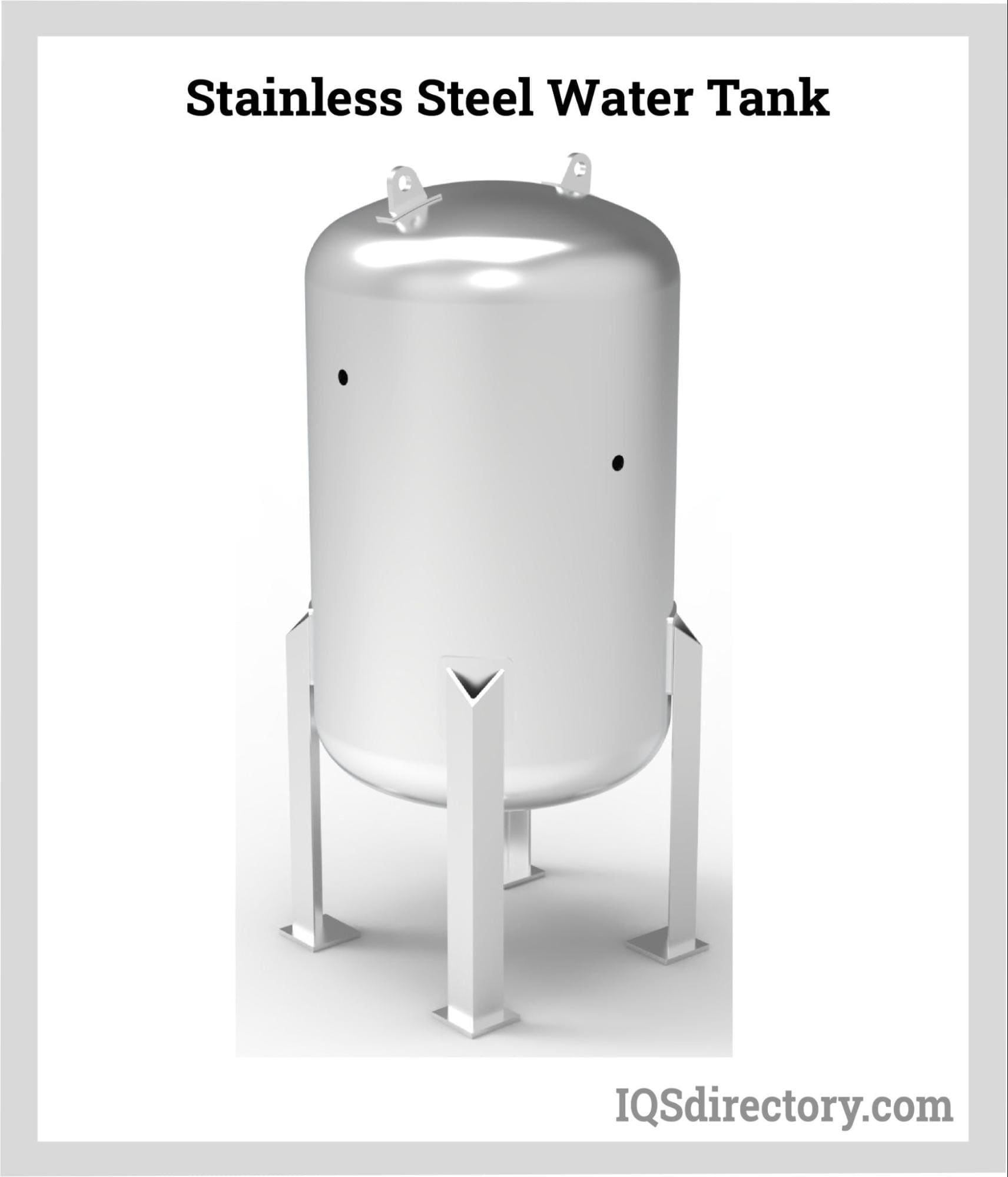

Water food grade tanks hold water for industrial, residential, and agricultural use and range in sizes from a few gallons up to tens of thousands of gallons. Water food grade tanks are made of a variety of materials including stainless steel, steel, and high grade plastics.

Types of Food Grade Tanks

Horizontal Tanks

Horizontal tanks may be located above or below ground. Their length is no greater than six times their diameter to ensure structural integrity. Horizontal tanks have pressure vacuum vents, gauge hatches, and sampling wells. They are an alternative for food storage when inside space has limited height.

Metal underground tanks are cathodically protected to prevent tank casing corrosion. They have galvanic anodes inside the tank or sacrificial anodes connected to an impressed current system that are used for cathodic protection.

Multi-Compartment Tank

Multi-compartment food grade tanks are designed to hold multiple food products with different temperature requirements and can have up to four individual compartments. The individual compartments are insulated to allow for the variations in temperature between the compartments, which are pitched for easy drainage.

Cone Bottom Tanks

Cone bottom tanks are funnel shaped with a drain at the center bottom of the tank. They are ideal for the storage of solid food materials and allow for easy access. The bottom of a cone bottom tank is referred to as its head and can be used for mixing or storing of food products. The design of cone bottom tanks ensures that all ingredients are drained from the tank since it has a 12o pitch to it. Cone bottom tanks work well with mixers and are customizable to fit the needs of a process.

Cook and Chill Tanks

Cook and chill tanks are designed to cook meat, poultry, vegetables, and pasta to a "just-done” limit after which the food is chilled for storage such that it can be reheated. The cooking process for a cook and chill tank is completed using steam from a boiler, a heat transfer process, direct fire, or electric heating. Most cook and chill tanks are made of stainless steel and are programmable.

The process for cook and chill tanks is also used to complete hands-free mixing of ingredients. Operators program the temperature and the speed of the agitator. The cook and chill tank completes the process without any further interference. A major benefit of cook and chill tanks is the reduction of manpower required to complete cooking processes. Cook and chill tanks are used by large food service organizations such as hospitals and universities.

Slope Bottom Tanks

Slope bottom tanks have a flat bottom that slopes at an angle on one side, which guides product to the side outlet for access and release. They are used with low viscosity fluids like milk, broths, and lighter granular products.

Food Grade Silos

Food grade silos are vertical storage units that can hold between one thousand and ten thousand gallons. They are an efficient space saving method for storing products and keeping them protected. In most cases, food grade silos are custom made from steel and stainless steel to meet the specific needs of customers. Smaller food grade silos are made from plastic and come with sloped, flat, dish, and cone shaped bottoms.

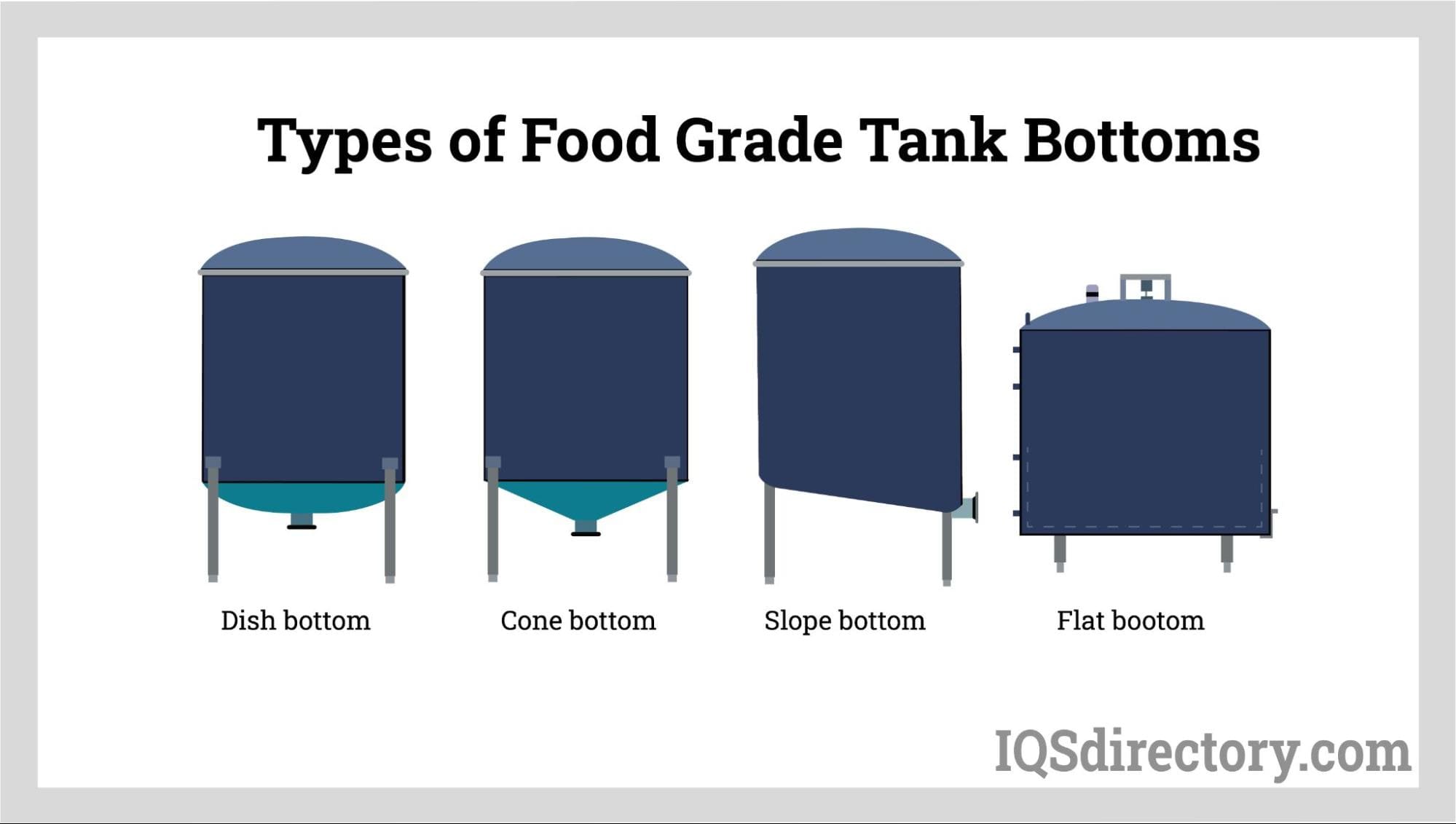

Food Grade Tank Bottoms

The bottom of a food grade tank, referred to as the head, is an essential part of a tank since its design will enhance the use of a tank and increase its efficiency. In most cases, the bottom of a food grade tank isn’t something that most clients consider when purchasing a food grade tank. It becomes a factor when dispensing product from a tank and can cause complications.

The four basic bottoms to food grade tanks are flat, sloped, cone shaped, and dish. The various types of bottoms have to align with the process that they are connected with, which can be mixing, storing, draining, or recirculating and may include proprietary processes.

Cone Bottoms

Cone bottoms are funnel shaped and have a drain at the center and bottom of the funnel. The cone shaped bottom is the most common one used in food processing since it makes it easier to drain products with a high solid content. Cone bottoms are ideal for the limitation of fluid flow.

Dish Bottoms

Dish bottom tanks have a similar construction as that of cone bottom tanks except that the bottom has the shape of a dome with a drain at the lowest part of the curve of the dome. The shape of a dish bottom helps in fluid circulation and is a better geometry for solid suspensions and slurries. The dome shape of dish bottom tanks makes them more rigid due to the strength of the curve of the dome and its knuckle radius.

Slope Bottoms

The major benefit of slope bottoms is the ease of access to the drain that sticks out away from the bottom of the tank. The angle of the slope of a slope bottom tank can be adjusted to better fit the application for which it is used.

Flat Bottoms

Flat bottoms are the most flexible of the bottom configurations since they can adapt to a variety of processes and have moderate fluid and solid flow. Of the four forms of bottoms, flat bottoms are the least expensive because of their simple design and ease of manufacturing. Flat bottom food grade tanks require a shorter mixing shaft than that designed for cone and dish shaped bottoms. The drawback of flat bottoms is that the tanks do not drain well, which limits the products that can be mixed or stored in them.

Choosing the Right Food Grade Tank Manufacturer

To make sure you have the most positive outcome when purchasing food grade tanks from a food grade tank manufacturer, it is important to compare at least 5 manufacturers using our food grade tank directory. Each food grade tank manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each food grade tank business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple food grade tank businesses with the same form.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

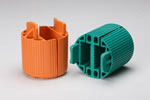

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services