Stainless steel is used everywhere, from zippers to skyscrapers; it is a vital part of our lives. Stainless steel is strong, corrosion resistant, low maintenance, and 100% recyclable. Stainless steel bins are used for transporting and holding solid chemical waste. They are used widely in agricultural, food, and chemical industries to contain solids like granulated sugar, chemicals, grains, and even waste.Read More…

Here at Frain Industries, Inc. we offer an extensive line of stainless steel tanks. These tanks come in a wide range of shapes and sizes based on their application. Our tank sizes range from 5 gallons to 10,000 gallons and these tanks can be customized to meet your application needs.

For 50 years G & F Manufacturing has been a leading quality stainless steel tank manufacturer for many industries, including pharmaceutical, food & beverage. Their storage containers offer quality workmanship & durability.

Rexarc’s focus is on the fabrication of custom stainless and carbon steel pressure vessels. We welcome applications with pressures between 500 and 5,000 psi. After nearly 100-years of being in business, Rexarc has the knowledge, attitude, equipment, and processes to support your needs in vessel production and value add services of piping, instrumentation, paint, and other controls...

At Weston & Associates, we take pride in our extensive range of stainless steel tanks, meticulously designed and crafted to cater to a myriad of industries. Our tanks are not just products; they are a testament to our relentless pursuit of quality and functionality. We understand that each client is unique, and our diverse portfolio of tanks reflects our adaptability in customizing solutions that ...

At True-Blue Welding and Fabrication LLC, we pride ourselves on our expertise in crafting high-quality stainless steel tanks. Our journey is defined by a relentless pursuit of perfection and a commitment to meeting the diverse needs of our clients. Join countless satisfied clients who have entrusted us with their most demanding projects and experience the True-Blue difference today.

Badger Fabrication is a family owned, custom stainless steel and waterjet cutting fabricator. We serve the food, diary and construction industry. Our state-of-the-art capabilities and craftsmanship will provide the quality, design and performance your application requires. We can provide finished products such as single shell tanks, mixers, enclosures, sanitary fittings, conduit hangers and more.

We offer a full range of stainless steel tanks such as vertical single wall tanks, process columns, portable mix tanks, cooking & pasteurizing kettle, specialty tanks, and more. We are committed to assisting you with finding a tank that meets your needs and these reliable products are very affordable.

More Stainless Steel Bin Manufacturers

Characteristics of Stainless Steel Bins

- Stainless steel bins are non-porous and highly resistant to chemicals and corrosion.

- The capacity of a stainless steel bin can vary from 20-50 cubic feet.

- The bins can be stacked or hanging and are usually rectangular in shape.

- The stainless steel bins are open-top containers with hinged lids, flat sides, and a sloping bottom.

- For ease, the open-top containers are mounted on a portable base or a steel frame with casters to transfer material directly into the bin.

- Some bins act like a hopper. A door at their conical bottom pours out liquid at controlled rate.

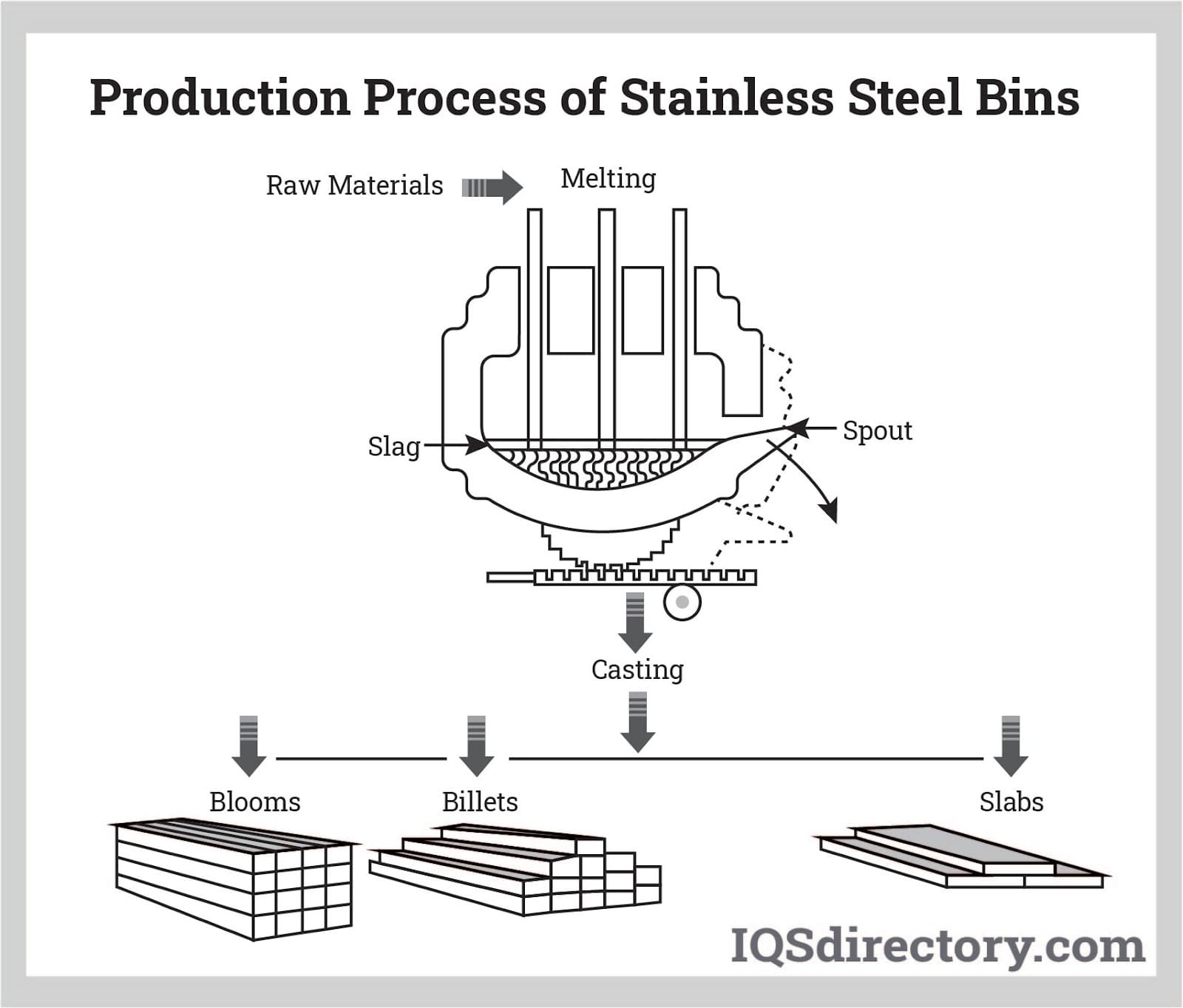

Production of Stainless Steel Bins

The production of stainless steel bins is a multi-step process. Steel scrap is melted, cast into a solid shape, heated up, cleaned, and polished.

Melting and Casting

The steel is put into a furnace alongside various alloy metals. It may take 8-10 hours for the steel to melt. The refined steel is then extracted and put into molds.

Forming

Next, the steel is hot rolled and formed into cast steel. Large rollers turn the cast steel into a thinner, longer form. Hot rolling takes place above the steel’s recrystallization temperature, and cold rolling happens below it.

Heat Treatment

Heat treatment strengthens the rolled steel. The steel is treated at a high temperature then slowly cooled down.

Descaling

In the heating process, the rolled steel has an oxidized layer on it. Descaling is the process of removing this layer to restore the shiny surface of the steel.

Cutting

Stainless steel can be cut by plasma cutting, water jet cutting and more.

Finishing

Manufacturers will ‘finish’ the steel to add corrosion-resistant properties, make it easier to clean, and give the steel a polished look. Stainless steel totes are similar to stainless steel bins. They are also rectangular containers used to transport and store fluids. Stainless steel totes can be stacked easily as they are covered and are collapsible when not in use.

Types of Stainless Steel Bins

There is many uses for stainless steel bins. The bins themselves differ in terms of size, placement, construction, and application. Some of these bins are as follows:

Stainless Steel Bin Boxes

These boxes are used to store fluids or solids in industries or households.

Stainless Steel Tote Baskets

Stainless steel tote baskets are used for placing solid objects for transport for storage.

Metal Waste Containers

These containers are used for disposing of waste in industrial facilities and individual households. Some metal waste containers include push lids or step-open pedals to make it easier to dispose of waste.

Wall-Mounted Waste Containers

These waste bins are mounted on walls to free up the ground space.

Touch-Free Waste Containers

These waste containers work automatically. Just wave a hand and the lid will open and close automatically.

Outdoor Cigarette Waste Containers

These cigarette waste containers help in keeping the outdoor environment clean and tidy. The narrow neck of this waste bin helps in extinguishing internal fires and the wide base provides stability.

Dual Compartment Step Open

Recycling and waste disposal is both done at the same time in this bin without mixing them up. These bins are hands-free and the lid closes softly.

Food Industry Stainless Steel Drum

The drums or bins used in the food industry are welded enough to close the seams for drainage of food from the container.

Wipe Dispensers

These bins or dispensers are used to hold hand wipes for cleaning purposes and are available in almost every public place.

Applications of Stainless Steel Bins

- Stainless steel bins are used in our everyday life for waste disposal.

- Industries use large steel bins for storing and transporting solids and other fluids from one place to another.

- Stainless steel bins are used in the medical and pharmaceutical industry for waste disposal or storing sterile equipment.

Choosing the Correct Stainless Steel Bin Supplier

To make sure you have the most productive outcome when purchasing stainless steel bins from a stainless steel bin supplier, it is important to compare at least 4 suppliers using our stainless steel bin supplier directory. Each stainless steel bin supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each stainless steel bin company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple stainless steel bin businesses with the same message.

55 Gallon Drums

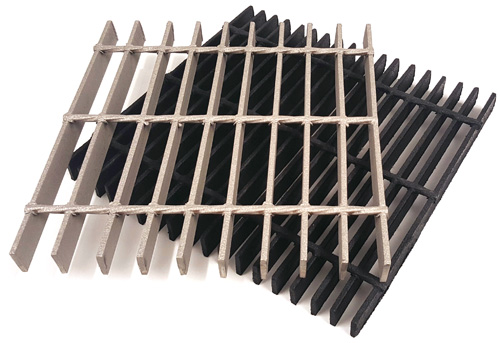

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services