Stainless steel storage tanks are used in industries such as food, chemical, dairy, pharmaceutical, cosmetics and many others where cleanliness and purity are needed. These tanks are widely used to store chemicals and gasses. Stainless steel tanks are highly resistant to chemical degradation; therefore, this material is a good choice. Read More…

Here at Frain Industries, Inc. we offer an extensive line of stainless steel tanks. These tanks come in a wide range of shapes and sizes based on their application. Our tank sizes range from 5 gallons to 10,000 gallons and these tanks can be customized to meet your application needs.

For 50 years G & F Manufacturing has been a leading quality stainless steel tank manufacturer for many industries, including pharmaceutical, food & beverage. Their storage containers offer quality workmanship & durability.

Rexarc’s focus is on the fabrication of custom stainless and carbon steel pressure vessels. We welcome applications with pressures between 500 and 5,000 psi. After nearly 100-years of being in business, Rexarc has the knowledge, attitude, equipment, and processes to support your needs in vessel production and value add services of piping, instrumentation, paint, and other controls...

At Weston & Associates, we take pride in our extensive range of stainless steel tanks, meticulously designed and crafted to cater to a myriad of industries. Our tanks are not just products; they are a testament to our relentless pursuit of quality and functionality. We understand that each client is unique, and our diverse portfolio of tanks reflects our adaptability in customizing solutions that ...

At True-Blue Welding and Fabrication LLC, we pride ourselves on our expertise in crafting high-quality stainless steel tanks. Our journey is defined by a relentless pursuit of perfection and a commitment to meeting the diverse needs of our clients. Join countless satisfied clients who have entrusted us with their most demanding projects and experience the True-Blue difference today.

Badger Fabrication is a family owned, custom stainless steel and waterjet cutting fabricator. We serve the food, diary and construction industry. Our state-of-the-art capabilities and craftsmanship will provide the quality, design and performance your application requires. We can provide finished products such as single shell tanks, mixers, enclosures, sanitary fittings, conduit hangers and more.

We offer a full range of stainless steel tanks such as vertical single wall tanks, process columns, portable mix tanks, cooking & pasteurizing kettle, specialty tanks, and more. We are committed to assisting you with finding a tank that meets your needs and these reliable products are very affordable.

More Stainless Steel Storage Tank Manufacturers

Stainless steel is a type of iron alloy that contains a certain percentage of chromium to give this material corrosion-resistant properties. Stainless steel storage tanks vary in shape and size depending on the amount of liquids or compressed gasses they have to store. The storage capacity of these tanks can range from few liters to thousands of gallons. The tanks that are used in industries have several inlets and outlets for easy mixing or blending of the products. The construction of stainless steel tanks can vary depending on the application these are used for.

Properties of Stainless Steel

- Stainless steel is an alloy of iron, and like most other types of steel, it is made of carbon and iron.

- 10% chromium is mixed in to give corrosion resistance to this alloy.

- Stainless steel is the most widely used material in many industries due to its desirable properties.

- This material is highly durable and has high strength.

- Stainless steel has increased formability, easy fabrication, and long-lasting material.

- It has low and high temperature resistance and needs low maintenance.

- Stainless steel is environmental friendly, with great recycled properties and an attractive appearance.

- This material does not needed to be painted, coated or treated.

Grades of Stainless Steel in Tanks

Stainless steel has a wide range of grades, and each grade is known for its specific properties and performance. In storage tank fabrication, three grades of stainless steel are used. These are as follows:

Stainless steel 304 and 304L

This grade is made of 18-20% chromium, 8-11% nickel, and 2% manganese. It is the most commonly used grade because of its high corrosion resistance. It is also used in many applications because it is less expensive compared to other grades.

Stainless steel 316 and 316L

This grade contains 16-18% chromium, 10-14% nickel, 2-3% molybdenum, and 2% manganese. The addition of molybdenum makes it more resistant to corrosion; therefore, this material is used in tanks in highly corrosive environments.

Duplex stainless steel

Duplex stainless steel contains 20-28% chromium, 2-5% molybdenum, ad 5-8% nickel. It is a combination of austenitic and ferritic structures. It is highly resistant to corrosion and good for use in tanks that contain fluids such as chlorides.

Types of Stainless Steel Storage Tanks

Stainless steel storage tanks can be customized according to their function. These can be single-walled or double-walled, horizontal or vertical, and insulated or heated.

Single-Walled Tanks

- These are the simplest cylindrical stainless steel tank.

- They can be placed vertically or horizontally depending on the application.

- The single wall helps to prevent corrosion of these tanks.

- These tanks are used to store water for domestic use and also in manufacturing plants with liquid raw materials.

Double-Walled Tanks

- Double-walled tanks are used in cases where spillage is a risk, such as oil spillage prevention.

- One or both walls of these tanks are made of stainless steel, depending on where corrosion resistance is needed.

- Some double-walled tanks have insulation between these walls.

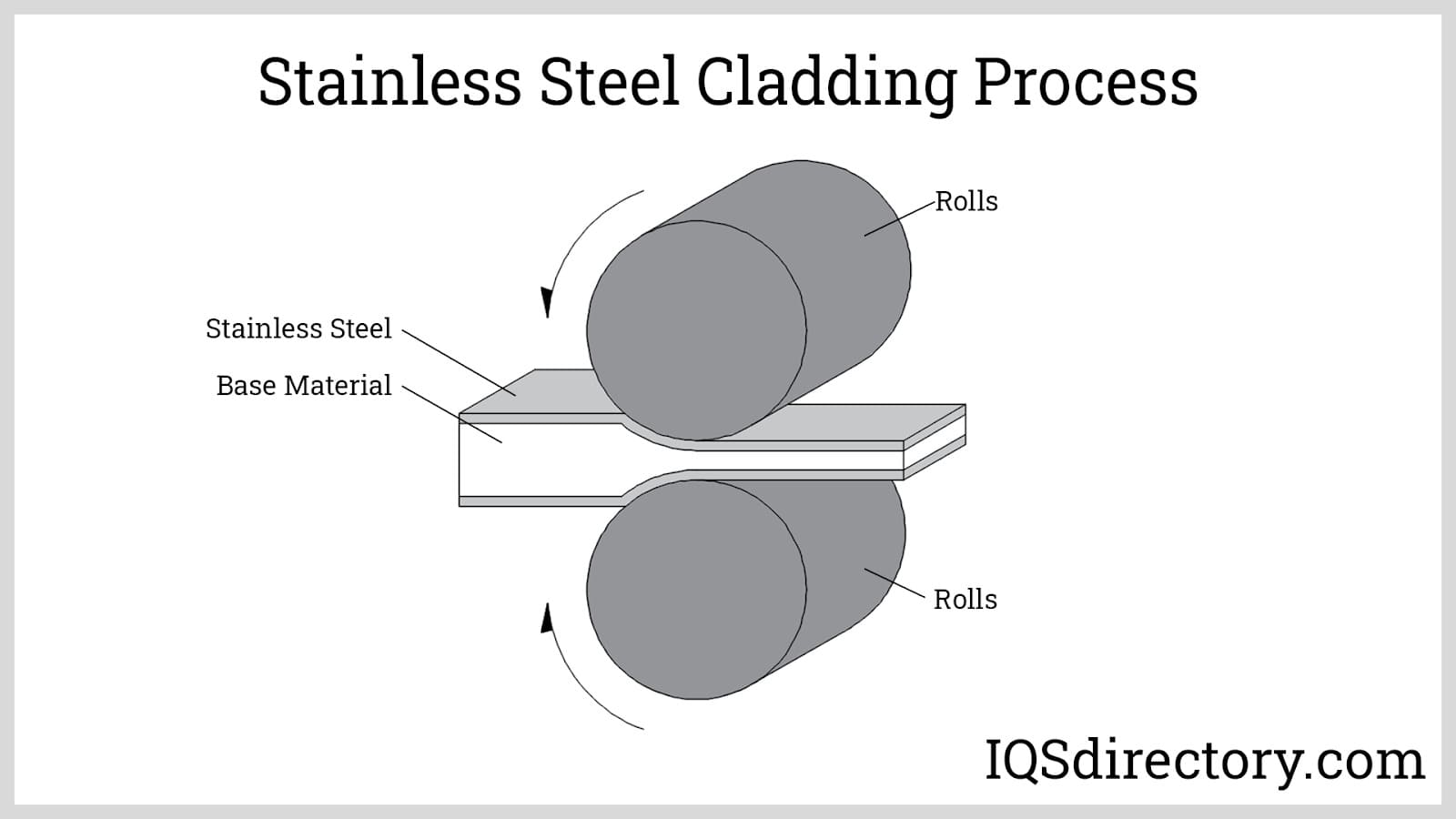

Stainless Steel Clad Tanks

- Large stainless steel tanks with thick walls are too expensive and impractical to use.

- Therefore, this tank is constructed with carbon steel plates and a thin sheet of stainless steel cladding.

- The carbon steel plates are subjected to static load, and the cladding is for corrosion prevention.

Jacketed Stainless Steel Tanks

- Jacketed steel tanks are used in processes that require additional cooling or thermal stability.

- The hot or cold air flows between the sheets of stainless steel plates.

- Three types of jackets are available. These are conventional jacket, dimple jacket, and half-pipe coil jacket.

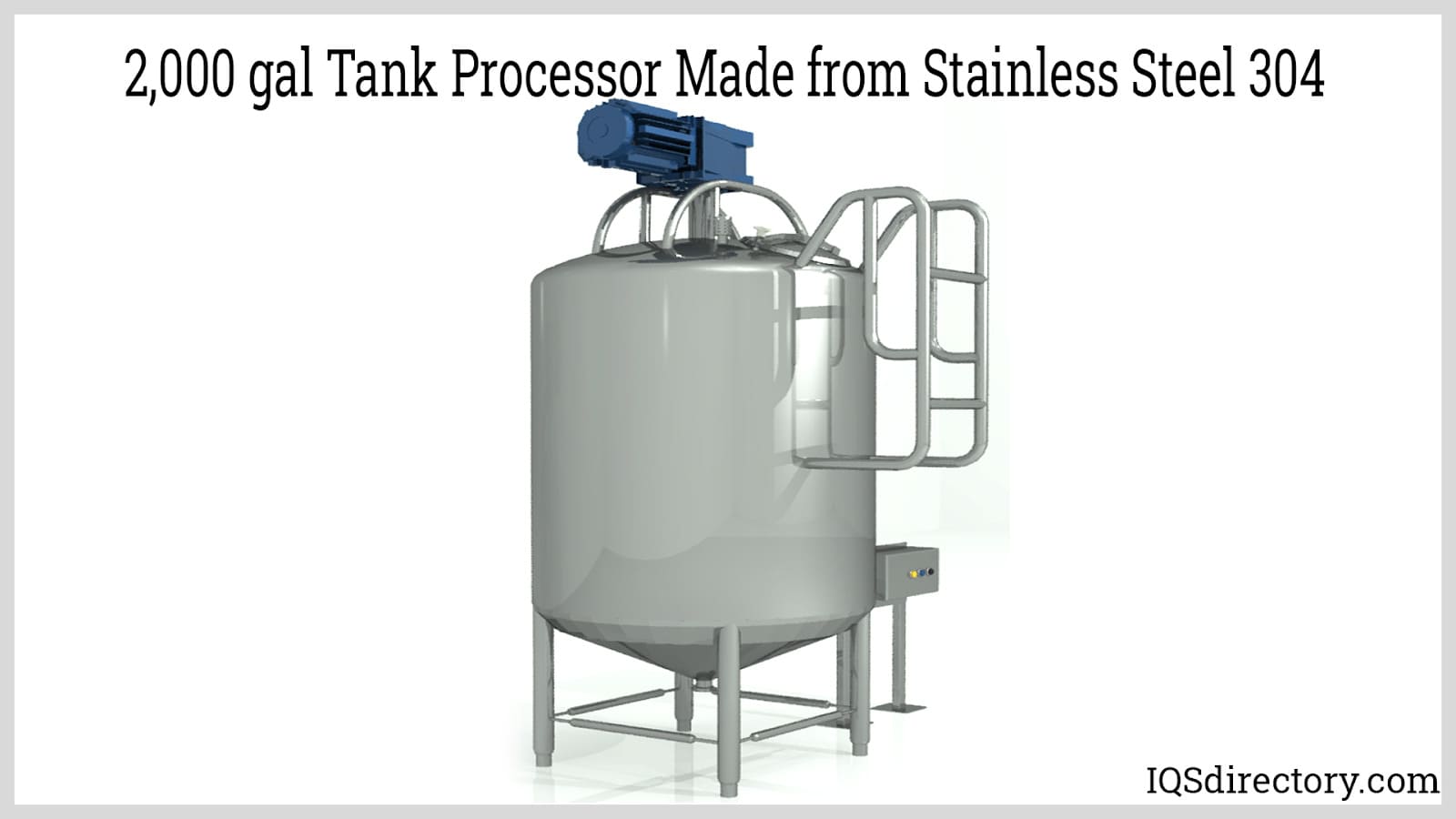

Stainless Steel Process Tanks

- This stainless steel tank is used in industrial plants for mixing, dissolving, or homogenizing the ingredients.

- These tanks contain an agitator or mixing head.

- Other instruments are installed in these tanks for controlling parameters such as temperature, pressure, etc.

High-Pressure Tanks

- Tanks used for domestic and commercial applications have low pressure to ensure the safety of workers.

- Certain certifications are added to high-pressure stainless steel tanks.

Compressed Air Tanks

- These tanks are used in industries with highly compressed air.

- Stainless steel tanks are used as air receivers.

- In these tanks, wet air is trapped and moisture is drained inside the vessel.

- As air and moisture are present in this vessel, corrosion-resistant materials should be used in these tanks.

Applications of Stainless Steel Storage Tanks

Stainless steel is a versatile material; therefore, it is used for a variety of applications. Some of the applications of stainless steel tanks are as follows:

- Stainless steel tanks are used as cold storage. Certain materials are resistant to low temperatures; therefore, these tanks are the best to store such materials.

- Many medical instruments and medicines are stored in stainless steel tanks.

- Stainless steel tanks are also used to store food items.

- These tanks are best suited for storage of certain reactive chemicals and other waste products.

- Stainless steel tanks are used for outdoor storage such as with oils.

Choosing the Proper Stainless Steel Storage Tank Supplier

To make sure you have the most beneficial outcome when purchasing stainless steel storage tanks from a stainless steel storage tank supplier, it is important to compare at least 4 to 5 companies using our list of stainless steel storage tank suppliers. Each stainless steel storage tank supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each stainless steel storage tank company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple stainless steel storage tank companies with the same form.

55 Gallon Drums

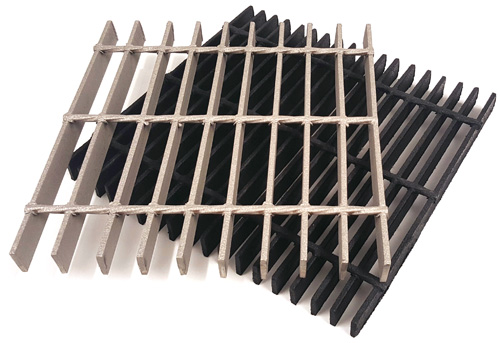

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services